A GRIST MILL WITH THE MOST ADVANCED

EQUIPMENT IN THE CZECH REPUBLIC

TECHNOLOGY

WE ARE THE MOST ADVANCED GRIST MILL IN THE CZECH REPUBLIC, PRODUCING 150,000 TONNES OF FLOUR ANNUALLY; THIS IS EQUIVALENT TO ABOUT 14% OF THE INDUSTRIAL PRODUCTION OF FLOUR IN THE COUNTRY. ALL OF THE MILL TECHNOLOGY HAS BEEN SUPPLIED BY BÜHLER.

MILL 1

PRODUCES THE ENTIRE RANGE OF OUR MILL PRODUCTS.

FLOURS CAN BE TREATED TO SUIT THE CUSTOMER’S REQUIREMENTS.

PRE-MILLING TREATMENT IS PROVIDED BY BÜHLER’S SORTEX,

A STATE-OF-THE-ART CLEANING MACHINE THAT SORTS OUT FOREIGN MATTER AND MOULDY KERNELS, which do not meet strict hygienic or quality criteria.

150 TONNES

DAILY PRODUCTION

CAPACITY

2000 TONNES

CAPACITY

OF GRANARY

1500 TONNES

FLOUR BINS

CAPACITY

MILL 2

THE MOST ADVANCED MILL TECHNOLOGY SUPPLIED BY BÜHLER IS INSTALLED IN THIS MILL.

PRE-MILLING TREATMENT IS PROVIDED BY BÜHLER’S SORTEX,

A STATE-OF-THE-ART CLEANING MACHINE THAT SORTS OUT FOREIGN MATTER AND MOULDY KERNELS, which do not meet strict hygienic or quality criteria.

240 TONNES

DAILY PRODUCTION

CAPACITY

1000 TONNES

CAPACITY

OF GRANARY

1500 TONNES

FLOUR BINS

CAPACITY

MILL 3

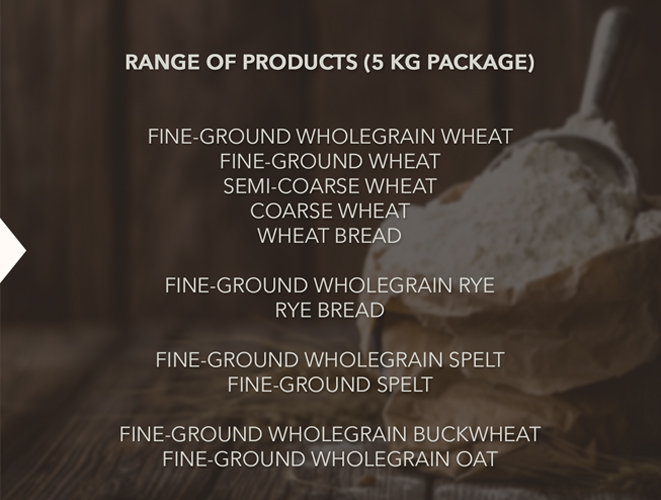

THIS IS THE MOST ADVANCED, FULLY AUTOMATED MILLING TECHNOLOGY FOR PROCESSING CEREAL GRAINS AND PSEUDOCEREALS, WHICH ENABLES THE PRODUCTION OF VERY FINE FLOURS, INCLUDING WHOLEGRAIN FLOURS WITH A GRANULE SIZE OF 160 MICROMETRES.

WE PRODUCE FINE-GROUND WHOLEGRAIN FLOURS FROM SPELT, RYE, BUCKWHEAT, OAT, RICE, BARLEY AND OTHER CROPS.

WE ALSO SUPPLY VERY FINELY GROUND WHEAT FIBRE.

THIS GRANULATION OF FINE-GROUND WHOLEGRAIN FLOURS TO THE SAME MILLING PARAMETERS AS USED FOR FINE-GROUND FLOUR GUARANTEES BETTER NUTRITIONAL QUALITIES AND IMPROVED WATER-BINDING CAPACITY, THUS OVERALL ENHANCED BAKING PROPERTIES AND LONGER SHELF-LIFE FOR THE END CUSTOMER.

THE PRE-MILLING TREATMENT IS PROVIDED BY BÜHLER’S SORTEX,

A STATE-OF-THE-ART GRAIN CLEANING MACHINE THAT CAN SORT OUT FOREIGN MATTER AND MOULDY KERNELS, which do not meet strict hygienic or quality criteria.

THE MILLING LINE ALSO INCLUDES THE MOST MODERN SIEVING CHECK AND A STERILISER FOR THE REMOVAL OF UNWANTED FOREIGN FRAGMENTS AND INSECTS.

100 TONNES

DAILY PRODUCTION

CAPACITY

300 TONNES

CAPACITY

OF GRANARY

300 TONNES

FLOUR BINS

CAPACITY

PACKING TECHNOLOGIES

WE HAVE PACKING TECHNOLOGIES ALLOWING THE PACKAGING OF FLOUR INTO 15-25 KG BAGS.

In the near future we are planning on opening a fully automatic packaging LINE, PRODUCING 0.5KG AND 1KG PACKAGES AT A MAXIMUM CAPACITY OF 50 TONS PER 24 HOURS.

CERTIFICATES

OUR CERTIFICATES ARE A GUARANTEE OF OUR PRODUCTION QUALITY.

QUALITY

WE HAVE OUR OWN QUALITY CONTROL LAB.

OUR TECHNOLOGY DETERMINES THE PRIMARY PARAMETERS OF FLOURS SUCH AS moisture and the NITROGEN SUBSTANCES content. MEASURING PARAMETERS SUCH AS DAMAGE TO STARCH AFTER MILLING AND determination of baking dispositions ARE A STANDARD PRACTICE.

LABORATORY EQUIPMENT

CHOPIN

ALVEOLAB, ALVEOGRAPH, CONSISTOGRAPH A SDMATIC

BRABENDER

EXTENSOGRAPH AND FARINOGRAPH

PERTEN

NIR ANALYZER

METTLER TOLEDO

DRYING SCALE TO MEASURE MOISTURE

WE MEASURE THE FALLING NUMBER AND CAN DETERMINE

THE VOMITOXIN LEVEL (DON).

LOGISTICS

WE DELIVER OUR FLOUR TO OUR CUSTOMERS’ PRODUCTION PLANTS, WAREHOUSES AND GRANARIES. DELIVERY IS POSSIBLE THROUGHOUT THE CZECH REPUBLIC AND ABROAD.

BULK FLOURS

WE DELIVER GOODS WITH OUR EIGHT MAN/MERCEDES TANKERS.

A SEMI-TRAILER CAN ALSO BE ATTACHED TO ANY OF THESE TRUCKS.

PACKAGED FLOURS

PACKAGED FLOURS ARE TRANSPORTED USING BOX TRUCKS WITH A CAPACITY OF 9 TONNES. THE SURFACE OF THE LOADING AREA COMPLIES WITH TRANSPORTATION HEALTH STANDARDS.

Basic products

WITH THE LATEST TECHNOLOGY, OUR GRIST MILLS PRODUCE FLOURS OF THE BEST QUALITY FOR THE LARGEST PRODUCERS OF BAKERY PRODUCTS IN THE CZECH REPUBLIC AND EUROPE.

WHEAT FLOUR

SPECIAL BAKER’S FINE-GROUND

FINE-GROUND PASTRY

FINE-GROUND BREAD

SUPERIOR-QUALITY MEDIUM-GROUND

WHOLEGRAIN

BUCKWHEAT FLOUR

FINE-GROUND

OAT FLOUR

WHOLEGRAIN

RICE FLOUR

FINE-GROUND

RYE FLOUR

FINE-GROUND BREAD

WHOLEGRAIN

WHEAT PRODUCTS

THERMOSTABLE FIBROUS MATERIAL

BRAN FOR A HEALTHY LIFESTYLE

FEEDSTUFFS

FEED FLOUR

BRAN

WE CAN PRODUCE FLOUR FROM OTHER TYPES OF CEREALS ACCORDING TO YOUR INDIVIDUAL NEEDS.

SUPPLIERS

OUR SUPPLIERS ARE PRIMARILY FARMERS AND CO-OPERATIVES FROM THE LOCAL AREA, BUT WE ALSO BUY GRAIN FROM OTHER REGIONS OF THE CZECH REPUBLIC. PURCHASING CEREAL GRAINS IS CONTRACT-BASED AND SUPPORTED BY THE RESULTS OF LABORATORY TESTING. TYPICALLY, CUSTOMERS DELIVER THEIR CEREAL GRAINS USING THEIR OWN MEANS OF TRANSPORTATION; THE PERNER MILL ALSO PROVIDES COLLECTION WITH ITS OWN VEHICLES. WE PURCHASE A WIDE RANGE OF CEREAL GRAINS.

FINE-GROUND WHOLEGRAIN FLOURS

THE NEW SPECIAL GRINDING EQUIPMENT FOR GRINDING WHOLEGRAIN FLOURS IS SUBSTANTIALLY DIFFERENT FROM COMMONLY EMPLOYED PROCEDURES. THE MAIN ADVANTAGE OF THE ABOVE-MENTIONED INNOVATIVE TECHNOLOGY IS A GENTLER GRINDING PROCESS THAT RESULTS IN BOTH A FLOUR PARTICLE SIZE AND, IN PARTICULAR, BRAN-DERIVED PARTICLES THAT ARE COMPARABLE TO THOSE OF FINE-GROUND FLOURS. THIS NEWLY APPLIED METHOD FOR PRODUCING WHOLEGRAIN FLOURS IN A SPECIAL FLOUR-MILL RELIES ON THE USE OF A HIGH-SPEED GRINDING ROLLER WITH VERTICAL AXIS ROTATION THAT HELPS TO MINIMISE ANY MECHANICAL AND THERMAL DAMAGE TO THE INTERNAL STRUCTURE OF THE FLOUR. WHOLEGRAIN FLOURS THAT ARE GROUND USING THIS TECHNOLOGY HAVE REMARKABLE TECHNOLOGICAL AND SENSORY PROPERTIES, A HIGH CONTENT OF FIBROUS MATERIAL AND A HIGHER CONTENT OF BETA-GLUCANS. THANKS TO THE GENTLE GRINDING PROCESS, NO SIGNIFICANT DAMAGE OCCURS TO THE STARCH. THE FINE SIZE OF THE WHOLEGRAIN FLOUR PARTICLES ENSURES A LARGER ACTIVE AND REACTIVE SURFACE AREA FOR THE FLOUR, WHICH HELPS TO INCREASE THE RATE OF REACTION FOR CERTAIN PHYSICAL REACTIONS, SUCH AS WATER ABSORPTION CAPACITY.

WHEAT FLOUR

WHOLEGRAIN FINE-GROUND

BUCKWHEAT FLOUR

WHOLEGRAIN FINE-GROUND

OAT FLOUR

WHOLEGRAIN FINE-GROUND

BARLEY FLOUR

WHOLEGRAIN FINE-GROUND

RYE FLOUR

WHOLEGRAIN FINE-GROUND

SPELT FLOUR

WHOLEGRAIN FINE-GROUND

UPON SPECIAL REQUEST, WE CAN ALSO PRODUCE WHOLEGRAIN FINE-GROUND FLOURS FROM OTHER CEREALS AND PSEUDOCEREALS.

TECHNOLOGICAL BENEFITS:

PARTICLE SIZE COMPARABLE TO THAT OF FINE-GROUND FLOURS

WATER ABSORPTION CAPACITY EXCEEDS 70%

A VERY GENTLE GRINDING PROCESS

MINIMAL DAMAGE TO AMYLUM GRAINS AND FLOUR STRUCTURE

PERFECT MECHANICAL PROCESSING

LARGER ACTIVE AND REACTIVE SURFACE AREA FOR THE FLOUR

ADVANTAGES OF THE FINAL PRODUCT:

LARGER VOLUME AND FLOUR EXTRACTION

LONGER DURABILITY AND FRESHNESS

BETTER SENSORY PROPERTIES

IMPROVED NUTRITION VALUES

LOWER GLYCEMIC INDEX

SUPPLIERS

OUR SUPPLIERS ARE PREDOMINANTLY LOCAL FARMERS AND AGRICULTURAL COOPERATIVES. IN ADDITION, WE PURCHASE CEREALS FROM OTHER LOCATIONS IN THE CZECH REPUBLIC. THE PURCHASE OF CEREALS IS CONTRACTED BASED ON THE RESULTS OF LABORATORY TESTS. CUSTOMERS GENERALLY SUPPLY GRAIN BY THEIR OWN MEANS OF TRANSPORT. IN ADDITION, PERNER MILL ENSURES TRANSPORT BY ITS OWN FLEET OF DELIVERY TRUCKS. WE PURCHASE A WIDE RANGE OF CEREAL VARIETIES

RETAIL

YOU CAN BUY FRESHLY GROUND FLOUR FROM THE PERNER MILL

DIRECTLY FROM US.

FAMILY FLOUR PACK (15 KG)

WHEAT FLOUR, FINE-GROUND

CZK 270,- INCL. VAT

WHEAT FLOUR, SEMI-COARSE

CZK 270,- INCL. VAT

WHEAT FLOUR, COARSE

CZK 270,- INCL. VAT

WHOLEGRAIN WHEAT FLOUR

CZK 270,- INCL. VAT

WHEAT BREAD FLOUR

CZK 270,- INCL. VAT

RYE BREAD FLOUR

CZK 270,- INCL. VAT

SPELT FLOUR, FINE-GROUND

CZK 375,- INCL. VAT

“PERNERKA” FLOURS 1KG

WHEAT FLOUR FINE

20,- CZK

WHEAT FLOUR SEMI-COARSE

20,- CZK

WHEAT FLOUR COARSE

20,- CZK

WHOLE WHEAT FLOUR

20,- CZK

WHOLE RYE FLOUR FINE

20,- CZK

SPELT FLOUR FINE

25,- CZK

WHOLE SPELT FLOUR FINE

25,- CZK

BUCKWHEAT FLOUR

65,- CZK

RICE FLOUR FINE

45,- CZK

ORGANIC SPELT FLOUR FINE

35,- CZK

ORGANIC WHOLE SPELT FLOUR FINE

35,- CZK

ORGANIC WHOLE WHEAT FLOUR FINE

30,- CZK

ORGANIC WHOLE RYE FLOUR FINE

30,- CZK

SPECIAL FLOUR (2 KG)

BUCKWHEAT FLOUR

CZK 90, INCL. VAT

OAT FLOUR

CZK 90, INCL. VAT

OPENING HOURS

BUSINESS DAYS

6 AM TO 2:30 PM

LOCATION

MLÝN PERNER,

SVIJANY 17

CHECK AVAILABILITY

FOR LARGER VOLUMES

724 247 277

2018 FARMERS’ MARKETS

TURNOV

THE FIRST SATURDAY OF EVERY MONTH.

MNICHOVO HRADIŠTĚ

THE SECOND SATURDAY OF EVERY MONTH.

ALWAYS ONE STEP AHEAD

ABOUT THE MILL

PERNER GRIST MILL WAS ESTABLISHED IN 1420. DURING ITS HISTORY, IT HAS BEEN OWNED BY PROMINENT NOBLE FAMILIES.

AFTER ITS BOOM PERIOD IN THE FIRST REPUBLIC IN THE OWNERSHIP OF THE PERNER FAMILY, THE MILL WAS NATIONALISED IN 1948 BEFORE BEING RETURNED TO THE FAMILY IN RESTITUTION IN 1992.

FOLLOWING TWO DECADES OF DEVELOPMENT, THE PERNER FAMILY GRIST MILL NOW RANKS AMONG THE LARGEST DOMESTIC PRODUCERS OF FLOUR WITH THE MOST ADVANCED TECHNOLOGY AND LABORATORIES together with unique milling technology focusing on fine-ground wholegrain flours IN THE CZECH REPUBLIC. IT FOCUSES ON LOCAL GRAIN PRODUCERS AND TOP QUALITY PRODUCTS.

PERNER MILL STORY

BOHUMIL’S UNCLE JAN PERNER (1815-1845) WAS A PATRIOT AND A DEVELOPER OF RAILWAYS. JAN PERNER STUDIED AT THE TECHNICAL UNIVERSITY IN PRAGUE. AFTER BUILDING RAILWAYS IN RUSSIA, HE JOINED THE TEAM BUILDING EMPEROR FERDINAND’S NORTHERN RAILWAY IN 1837. HE ALSO PARTICIPATED IN EXTENSIVE RAIL WORK TO CONNECT VIENNA AND PRAGUE AND BECAME THE CHIEF ENGINEER OF THE STATE RAILWAYS. HIS DESIGN FOR THE PRAGUE – DRESDEN LINE WAS APPROVED BY THE EMPEROR IN 1842. JAN PERNER DIED IN 1845 UNDER TRAGIC CIRCUMSTANCES. TODAY, SEVERAL INTERCITY AND EUROCITY TRAINS CARRY HIS NAME, AS DO STREETS IN PRAGUE AND PARDUBICE, AS WELL AS THE FACULTY OF TRANSPORT OF PARDUBICE UNIVERSITY.

THE NEW TECHNOLOGY WAS SUPPLIED BY BÜHLER, A SWISS COMPANY; THE INSTALLATION ALONE COMPLIES WITH THE MOST DEMANDING REQUIREMENTS FOR QUALITY AND PRODUCTION SAFETY.

PRODUCTION IS DIVIDED INTO TWO SEPARATE MILLING PLANTS THAT CAN OPERATE EITHER INDEPENDENTLY OF EACH OTHER OR IN TANDEM. THE PERNER MILL IS THE SUPPLIER OF BULK FLOUR TO LEADING CZECH PRODUCERS OF BAKED AND CONFECTIONARY PRODUCTS. FLOUR IS ALSO SUPPLIED TO CUSTOMERS ABROAD.

PARTNERS

Collaborators

CONTACT DETAILS

Daniel Perner

MANAGING DIRECTOR

tel.: 485 177 106

Jan Perner

MANAGING DIRECTOR

TEL.: 485 177 106

ACCOUNTING:

Jitka Křižanovská

Tel.: 485 177 106

[email protected]

SALES:

Jitka Kočišová

Tel.: 485 177 129

[email protected]

© MLÝN PERNER SVIJANY SPOL S.R.O. 2018

This site uses cookies to ensure site functionality and traffic analysis. By using this site, you express your consent to the use of cookies.